Parallel Board To Board Connectors

PCB Connectors From Z-Axis Connectors

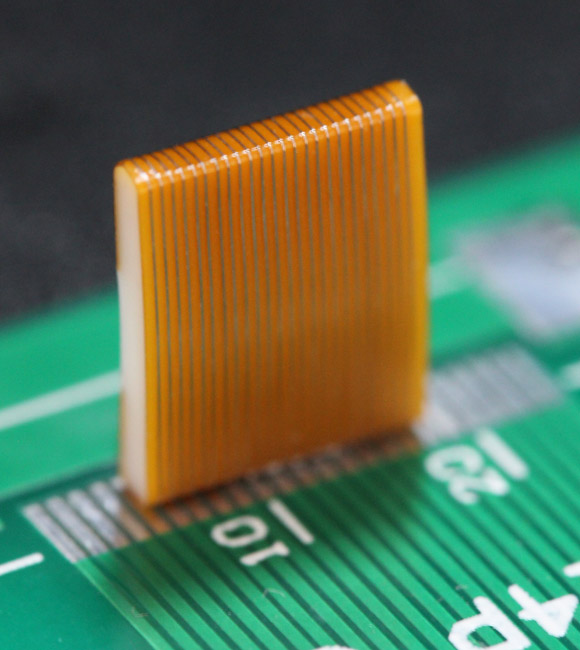

Z-Axis Connector Elements are compression style connectors that are squeezed between two boards to achieve electrical contact. In most applications, a retaining slot positions the element. Ribs in the slot allow for expansion during compression. Molding slots directly into the end-unit housing can achieve advantages in cost and ease of assembly. Surface-to-surface, gasket-like contact is made that allows for mating differing pad metallurgies such as gold flash, carbon ink, silver ink, or indium-tin-oxide (ITO).

In the pictured application, the main board is built with contact pads and accurately located mounting holes to accept four possible modules. Note that the modules can be at different heights. The connector cost for adding a module is not incurred until a module is needed. Complete connectors can be designed and built in days. Please contact us today for more information.

Advantages

Other advantages of using high density, solderless and one-piece Z-Axis Connector Elements for board-to-board connections are particularly evident when:

- Solder bridging of high-density connections is a problem.

- A low unit and tooling cost custom connection is required.

- Shock and vibration issues are a concern.

- Connectors need to be easily replaced.

- Vertical space is at a premium.

- Horizontal space is at a premium.

- Right angle connections are needed in a small physical space.

- Alignment of multiple high-density connectors is problematic during assembly.

- Existing fine pitch mechanical connectors are too fragile.