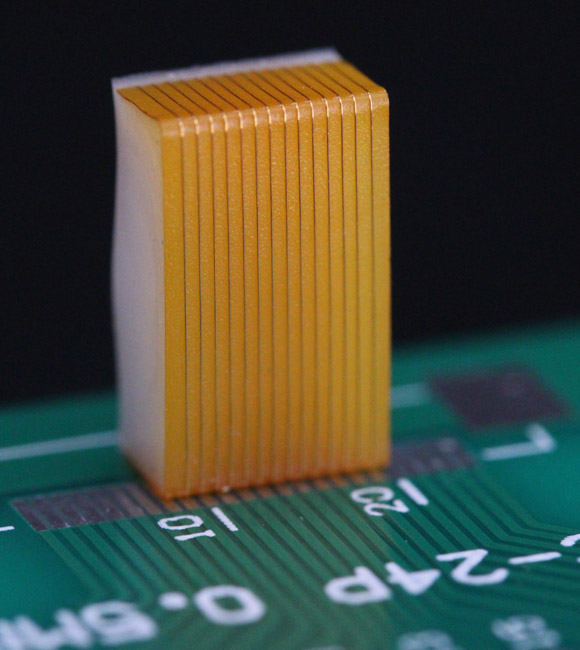

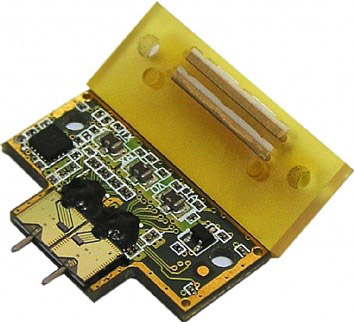

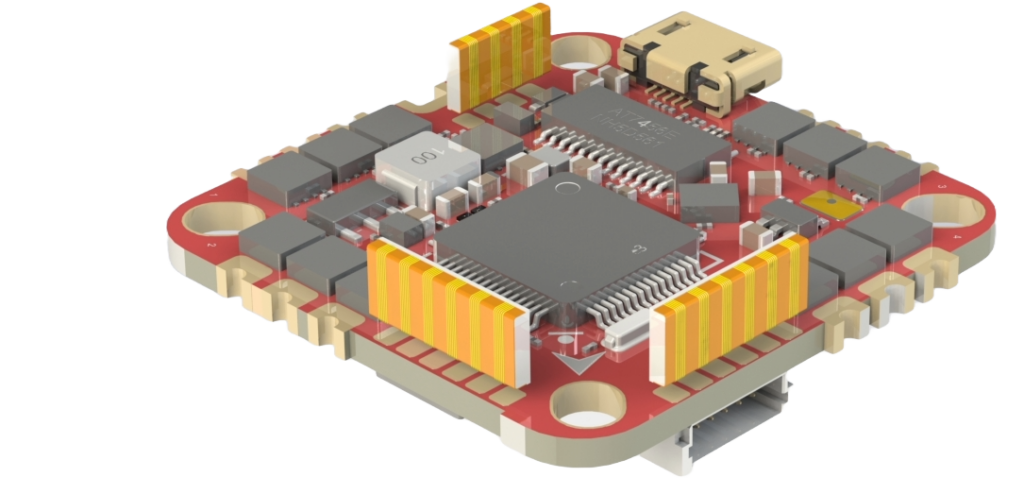

Choosing the right connector can significantly impact the performance, reliability, and cost-effectiveness of your design. Among the various options available, elastomeric connectors and spring-loaded pins are popular choices.

However, elastomeric connectors often stand out as a superior design choice for several compelling reasons. Here, we explore why elastomeric connectors outshine traditional pins in various critical aspects:

1. Misalignment Compensation

Elastomeric connectors are highly forgiving when it comes to misalignment between mating surfaces. The compressible nature of elastomeric material allows it to deform and accommodate slight misalignments, ensuring a reliable electrical connection even if the surfaces are not perfectly aligned. In contrast, spring-loaded pins require more precise alignment for a successful connection, which can complicate the design and assembly process.

2. Contact Pressure Distribution

One of the standout advantages of elastomeric connectors is their ability to provide a larger contact area and distribute contact pressure evenly across mating surfaces. This even distribution is particularly beneficial for applications with delicate or sensitive surfaces, as it reduces the risk of damage or deformation. Spring-loaded pins, with their localized contact points, can create high-pressure spots that may lead to wear and potential damage over time.

3. Shock and Vibration Resistance

Elastomeric connectors excel in dynamic environments where shock and vibration are common. Their inherent flexibility allows them to absorb and dissipate mechanical stresses, maintaining electrical contact without losing connectivity. This makes them ideal for applications in automotive, aerospace, and industrial settings where mechanical stability is crucial. On the other hand, spring-loaded pins can struggle to maintain consistent contact under similar conditions, leading to potential reliability issues.

4. Reusability and Durability

Elastomeric connectors boast impressive reusability and durability. They can be compressed and decompressed multiple times without significant degradation in performance, making them well-suited for applications requiring frequent disconnections and reconnections. While spring-loaded pins are durable, they may experience wear and fatigue over time, which can impact their long-term reliability. Elastomeric connectors offer a longer-lasting solution for high-cycle applications.

5. Cost-Effectiveness

In many cases, elastomeric connectors present a more cost-effective solution than spring-loaded pins, especially for applications demanding high-density interconnects. Elastomeric connectors can accommodate a larger number of conductive elements in a smaller form factor, reducing the overall cost per connection point. This cost advantage, combined with their superior performance characteristics, makes elastomeric connectors an attractive choice for many designers.

Conclusion

When it comes to choosing between elastomeric connectors and spring-loaded pins, elastomeric connectors offer numerous benefits that can enhance the performance, reliability, and cost-efficiency of your design. Their ability to compensate for misalignment, distribute contact pressure evenly, resist shock and vibration, provide long-term durability, and offer cost-effective solutions makes them a superior choice for a wide range of applications.

At Z-Axis Connector Company, we specialize in designing and manufacturing high-quality elastomeric connectors tailored to meet the unique needs of your applications.

Contact us today to learn more about how our elastomeric connectors can elevate your designs and provide reliable, long-lasting performance.