In high-volume manufacturing, every design choice impacts cost, efficiency, and production scalability. For consumer electronics and other mass-produced devices, selecting the right PCB interconnect solution is crucial to meeting both performance and cost targets. Z-Axis elastomeric connectors offer a superior alternative, providing an economical, easy-to-assemble, and reliable solution for high-volume applications.

Cost Efficiency in Large-Scale Production

When designing for mass production, cost per unit is a critical factor that directly impacts profitability. Every component in a high-volume product must be optimized for both material and manufacturing efficiency. Traditional connectors, such as fine-pitch board-to-board connectors, spring-loaded contacts, or custom flex circuits, often introduce hidden costs in production. These include:

- Precision Alignment Requirements:

- Many conventional connectors require highly precise placement to ensure proper electrical contact, increasing the need for fine-tuned pick-and-place assembly processes. Misalignment during assembly can lead to failed connections, requiring costly rework or scrap.

- Soldering & Additional Processing Steps:

- Most traditional connectors require soldering, which adds process complexity and increases manufacturing time. This also means additional costs for solder paste, reflow ovens, and post-solder inspection to ensure quality.

- Mechanical Retention & Fasteners:

- To ensure secure connections, some traditional connectors require extra mechanical retention features such as screws, clips, or latching mechanisms. These additional components not only add material costs but also increase assembly time.

- Connector Pin & Housing Costs:

- Many fine-pitch connectors require high-precision metal contacts and molded plastic housings, both of which can drive up material expenses—especially in high-density applications.

How Z-Axis Elastomeric Connectors Reduce Costs

Z-Axis elastomeric connectors address these challenges by offering a simpler, more cost-effective alternative:

- Solder-Free Interconnects:

- By eliminating the need for soldering, elastomeric connectors remove reflow processing steps, reducing labor costs and minimizing the risk of solder joint defects that could lead to product failures.

- Fewer Precision-Machined Components:

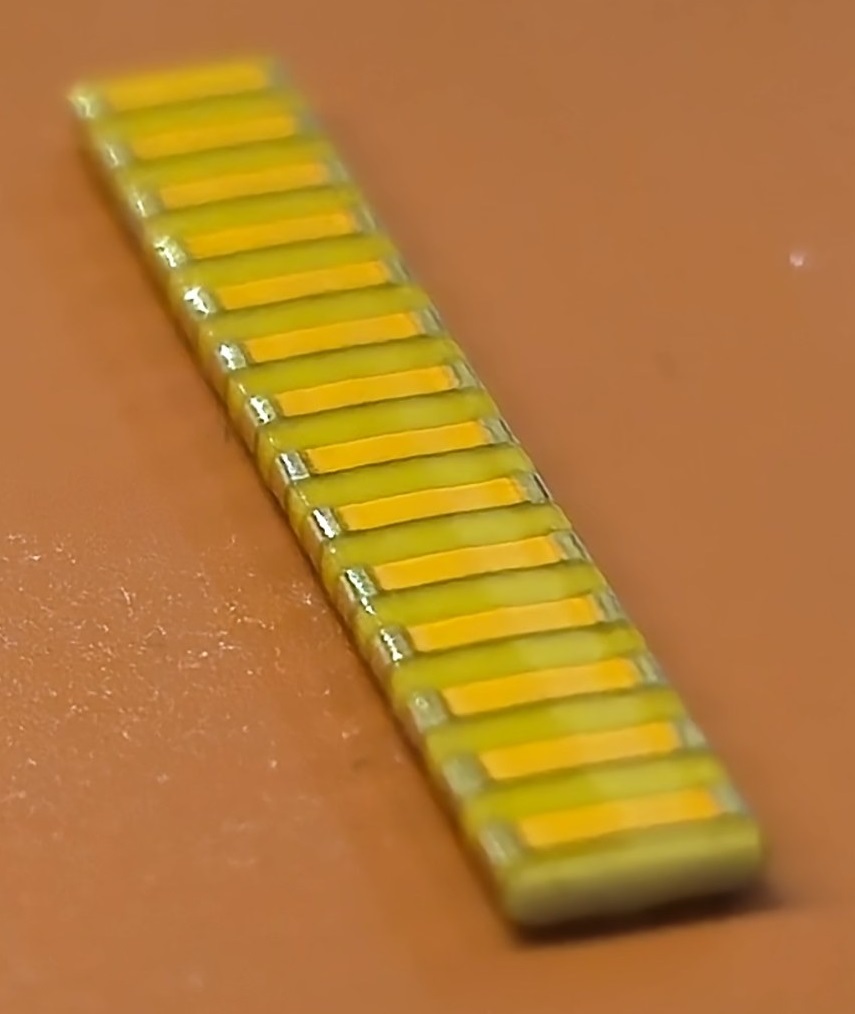

- Unlike traditional connectors that require finely machined metal pins and plastic housings, elastomeric connectors use a soft silicone structure with embedded conductive pathways. This design significantly reduces material costs while maintaining excellent electrical performance.

- Optimized for High-Density PCB Designs:

- Elastomeric connectors support fine-pitch, high-density contact arrays in a compact form factor, enabling designers to reduce PCB size and save valuable board space. This scalability allows manufacturers to design smaller, more cost-efficient products without compromising connectivity.

- Faster, Lower-Cost Assembly:

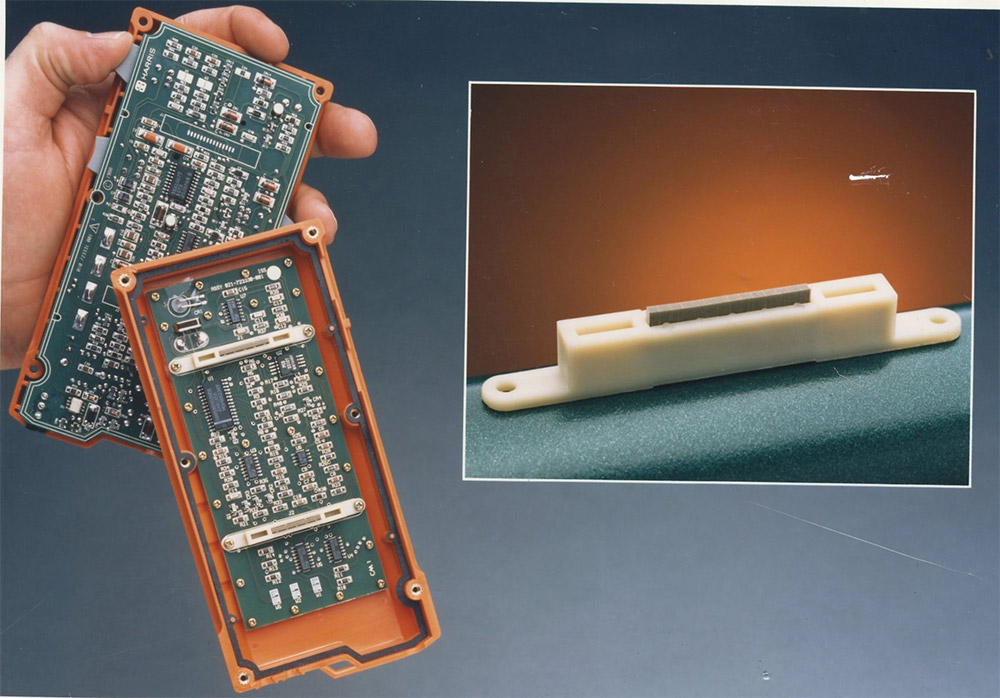

- These connectors can be easily placed and compressed into position without the need for intricate alignment or retention mechanisms, simplifying automated production lines and reducing per-unit assembly time.

For manufacturers producing thousands or millions of units, these cost-saving advantages quickly add up, making Z-Axis elastomeric connectors an economically viable choice for high-volume applications.

Reliable Performance in Consumer Electronics

Consumer devices demand reliable electrical connections that maintain performance despite repeated use, environmental exposure, and mechanical stress. Z-Axis elastomeric connectors excel in these applications by:

- Providing low and stable contact resistance, ensuring signal integrity over time.

- Offering superior vibration and shock resistance, ideal for handheld and mobile devices.

- Reducing mechanical wear compared to traditional spring-based or sliding contact connectors.

These features make elastomeric connectors a dependable choice for products requiring long-term reliability without the risk of mechanical failure.

Applications in High-Volume Markets

Z-Axis elastomeric connectors are well-suited for a variety of mass-produced electronics, including:

- Smartphones & Tablets:

- Space-saving interconnects for display modules and PCB stacking.

- Wearable Devices:

- Flexible, durable connections for compact and lightweight electronics.

- Consumer IoT Devices:

- Reliable data and power transmission for smart home products.

- Automotive Electronics:

- Vibration-resistant connectors for infotainment and control systems.

Upgrade Your Manufacturing Process Today

For companies scaling up production, Z-Axis elastomeric connectors offer a cost-effective, easy-to-assemble, and high-performance interconnect solution. By reducing material costs, streamlining assembly, and enhancing reliability, these connectors help manufacturers meet the demands of high-volume production while improving overall product quality.

Interested in integrating elastomeric connectors into your next high-volume design? Contact Z-Axis today to learn more about how our solutions can optimize your manufacturing process.

www.zaxisconnector.com