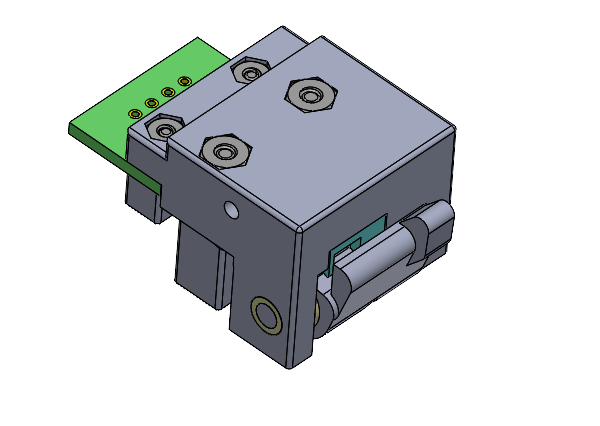

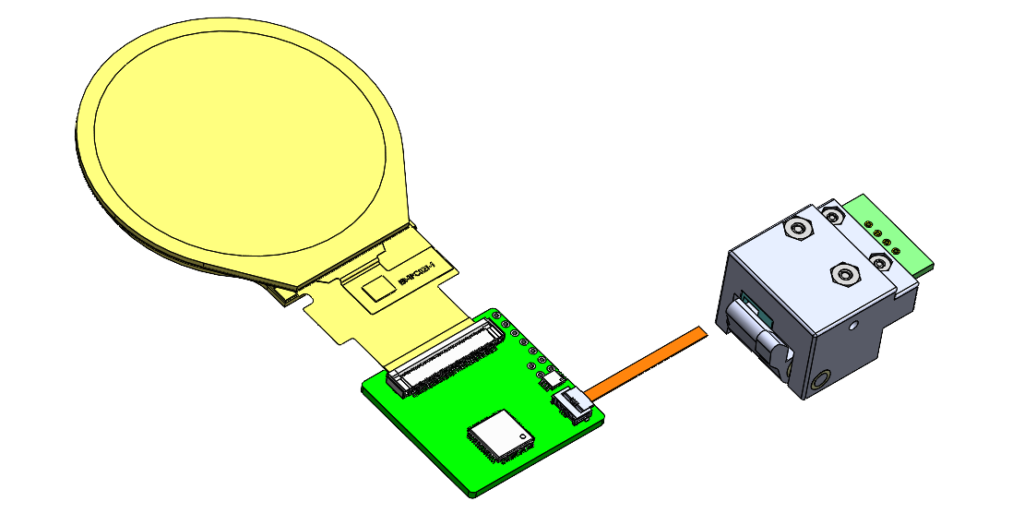

As electronics continue to become more compact, engineers and manufacturers face increasing difficulties in testing and programming components in restricted areas. Z-Axis Connector’s micro-fixtures offer a tailored solution, providing a small footprint while maintaining the high accuracy and functionality required for complex tasks.

Why Choose Micro-Fixtures?

When dealing with densely populated PCBs, intricate assemblies, or miniature components, conventional test fixtures can be cumbersome and ineffective. Micro-fixtures provide a more efficient option for testing in confined or hard-to-reach spaces, thanks to their streamlined design that allows access to even the most difficult areas of a device.

Key Features of Z-Axis Connector Micro-Fixtures:

- Ultra-Compact Design: Our micro-fixtures are engineered to occupy minimal space without sacrificing performance. This makes them ideal for environments where physical room is limited but precision is essential.

- Versatile Functionality: Z-Axis micro-fixtures support various testing needs such as continuity checks, signal integrity measurements, and contact resistance testing, all within one efficient setup.

- Easy Access to Difficult Areas: These fixtures are specifically designed to reach tight, hard-to-access components, ensuring fast and efficient testing in constrained spaces.

- Reliable Performance: Despite their small size, our micro-fixtures deliver consistent, repeatable results, making them ideal for rigorous industrial applications.

- Customizable Design: Z-Axis Connector also offers fixture customization to fit the unique needs of your project. Whether you require specific configurations or tailored adjustments for challenging applications, we can modify the design to ensure optimal functionality.

- Durability: Built for industrial use, our micro-fixtures are designed to withstand continuous operation without loss of accuracy or performance over time.

Tailored Solutions for Every Application:

In addition to our standard micro-fixtures, we understand that certain projects require customized solutions. Whether you need alterations for higher density PCB assemblies, non-standard components, or unique test environments, Z-Axis Connector can create fixtures that perfectly match your requirements.

Ideal Applications:

- Testing in Compact Assemblies: Our micro-fixtures allow precise testing of components located in tight spaces within consumer electronics, medical devices, or industrial equipment.

- Prototype Debugging: During prototype validation, space can be limited, and micro-fixtures make it easy to troubleshoot and verify intricate designs.

- High-Density PCB Testing: Perfect for dense PCBs where traditional test fixtures cannot reach, ensuring every component is tested effectively.

- Device Programming: Micro-fixtures allow simultaneous testing and programming of small devices, reducing the need for separate setups and saving time in production environments.

Benefits of Z-Axis Connector Micro-Fixtures:

- Space-Saving Efficiency: Their compact footprint helps maximize workspace without compromising on the thoroughness of your testing.

- Quick Integration: Easy to set up and incorporate into your workflow, these fixtures reduce the time spent on initial setup, ideal for both prototyping and high-volume production.

- Consistent Accuracy: Built with precision in mind, our fixtures ensure that each test is performed under controlled conditions, leading to dependable, repeatable results.

- Custom Fit for Your Needs: With the option for customization, we can develop a micro-fixture that perfectly fits your testing environment and specific challenges.

Conclusion

Z-Axis Connector’s micro-fixtures are the perfect choice for engineers and manufacturers needing reliable, high-precision testing in hard-to-reach areas. From standard configurations to fully customized solutions, our fixtures provide the flexibility, durability, and accuracy required to meet today’s complex testing demands.

Contact Z-Axis Connector today to discuss how our micro-fixtures can be tailored to your specific testing and programming needs.