Follow the guidelines below to ensure seamless integration and optimal performance when designing PCBs with elastomeric connectors

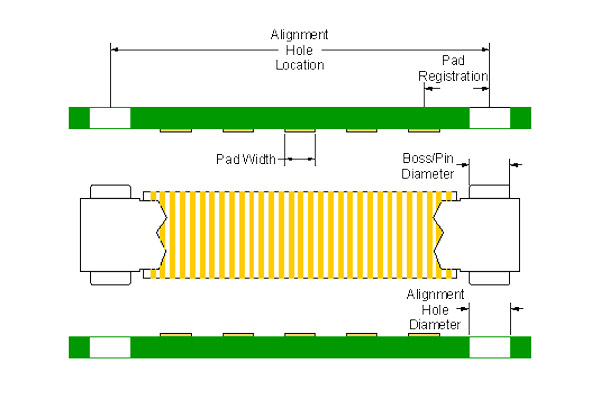

1. Mounting Holes and Fasteners for Connector Housing

Importance of Secure Mounting:

Proper mounting is crucial for maintaining alignment and ensuring a reliable electrical connection. The connector housing should be securely fastened to the PCB using appropriately sized mounting holes and fasteners.

Design Recommendations:

-

Mounting Holes:

Ensure the mounting holes are precisely aligned with the connector housing to prevent misalignment during assembly. These holes play a dual role, not only securing the connector but also aiding in the accurate alignment of the connector to the PCB. This alignment is essential to avoid stress on the connectors, which can lead to premature wear or electrical failures. -

Fasteners:

Use fasteners that provide adequate holding force without damaging the PCB or connector. Suitable options include pins, screws, bolts, or clips designed for the specific connector type. Fasteners should be chosen to maintain the mechanical stability of the connector without introducing excessive strain on the PCB. -

Alignment via Mounting Holes:

The mounting holes can also serve as alignment guides, ensuring that the connector pins or contacts align perfectly with the corresponding PCB pads. This is particularly important in high-density or multi-connector setups, where precise alignment prevents misalignment issues that could compromise the integrity of the electrical connections. -

Spacing:

Allow enough space around the mounting holes to accommodate the fasteners and any tools required for assembly. Adequate spacing ensures easy installation and maintenance, reducing the risk of damaging adjacent components during assembly.

2. Power vs. Signal Pads

Power and Signal Pads

Differentiating Power and Signal Connections

When designing PCB layouts for elastomeric connectors, it is essential to differentiate between power and signal pads to ensure reliable operation and longevity. Power connections typically carry higher currents, requiring specific design considerations compared to low-power signal paths.

Design Recommendations:

-

Pad Size & Width:

- Power pads should be wider and larger than signal pads to reduce resistance and improve current-carrying capability. Please contact us for application specific dimensional recommendations.

- Signal pads can be smaller but should still provide sufficient contact area for reliable connectivity.

-

Plating Considerations:

- Use hard gold plating for power pads when frequent mating cycles are expected, ensuring durability under higher current loads.

- Signal pads can also benefit from ENIG or hard gold plating for stable and consistent electrical performance.

-

Pad Spacing:

- Maintain adequate spacing between power and signal pads to prevent unintended coupling or crosstalk.

- For high-current applications, ensure enough separation to mitigate thermal buildup and avoid overheating issues.

-

Thermal Management:

- Power pads should be connected to sufficient copper pours or thermal relief structures to dissipate heat effectively.

- Signal pads generally do not require extensive thermal management but should be routed carefully to minimize noise and interference.

By optimizing the layout and treatment of power and signal pads, designers can enhance the efficiency and reliability of elastomeric connector implementations in their PCBs.

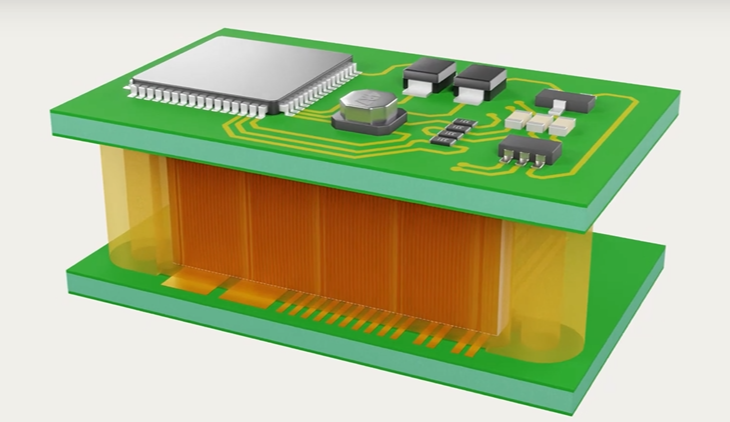

3. Hard Gold or ENIG Plated Pads

Zwrap Assembly - Hard Gold Plated Pads

Enhanced Contact Durability:Hard gold or Electroless Nickel Immersion Gold (ENIG) plating is recommended for elastomeric connector pads due to their superior wear resistance and conductivity.

Design Recommendations:

-

- Hard Gold Plating: Offers excellent wear resistance, making it ideal for applications involving frequent mating and unmating. This ensures a long-lasting, reliable connection. For long-term production applications, we recommend a 30mircoinch minimum plating thickness.

-

- ENIG Plating: Provides good corrosion resistance and electrical conductivity, suitable for high-performance applications.

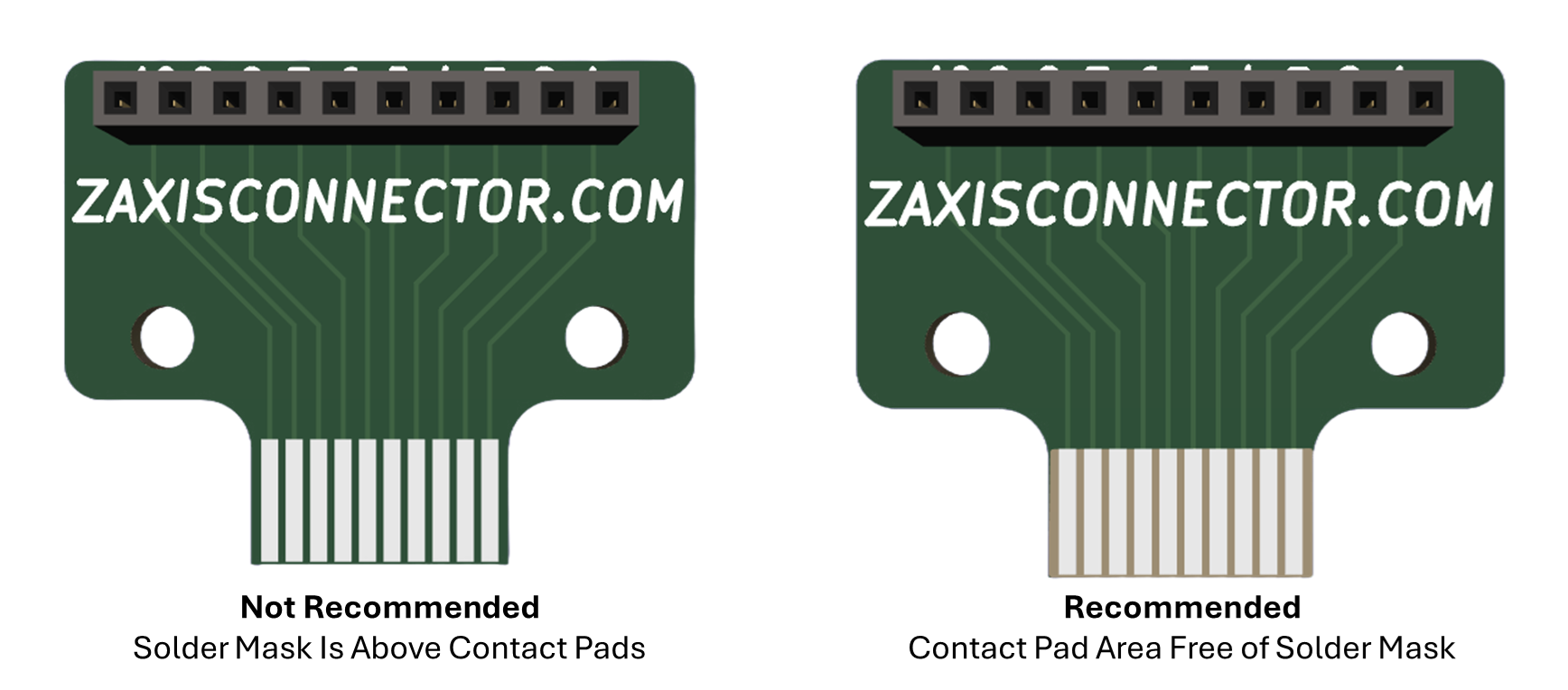

4. No Soldermask on Contact Pads

Optimizing Electrical Contact:

To achieve the best possible connection, the contact pads for elastomeric connectors should be free of soldermask. This ensures a clean, unobstructed contact surface.

Design Recommendations:

-

- Soldermask Clearance: Ensure that the soldermask is completely removed from the contact pad area. This eliminates any barriers that could interfere with the connector's ability to establish a solid electrical connection.

-

- Pad Finish: Maintain a smooth and clean surface on the contact pads to ensure optimal contact with the elastomeric connector.

By following these guidelines, engineers and designers can effectively integrate elastomeric connectors into their systems, ensuring reliability and performance.

Contact us today!