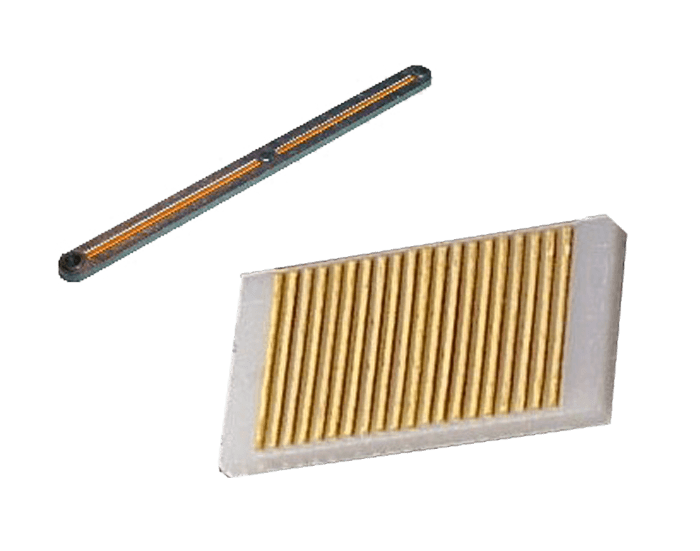

Z-Con connector

Z-Con Connector Assembly

Z-Con Assemblies are made with Z-Axis Connectors inserted into standard or custom housing shells. They are the equivalent of traditional mechanical connectors and are available in single or multiple slot configurations or arrays. Using Stereo Lithographic Rapid Prototyping Techniques, custom shells for low cost prototypes can be provided in days. Simple molded slot housings can be production tooled for under $3500 US.

Standard sizes are available, please contact us directly for availability.

Z-Con Features & Benefits

Wire Metallurgy

We maintain a stock of the following wire types:

- Z-Alloy

- Gold Plated Copper

- Gold

We are able to build connector elements with almost any wire and will respond to special requests for materials such as Chromel, Alumel, Inconel, etc… We will also work with wire supplied by our customers, as long as the material is continuous. We also work with conductive polymer fibers.

Rubber Core

Outline Dimensions and Tolerances

The minimum standard dimensions and typical tolerances are:

Length: 0.50 mm +/- 0.250 or 0.020 inches +/- 0.010

Height: 0.50 mm +/- 0.125 or 0.020 inches +/- 0.005

Width: 0.50 mm +/- 0.125 or 0.020 inches +/- 0.005

The maximum standard dimensions and typical tolerances are:

Length: 20 cm +/- 0.250 or 8.00 inches +/- 0.010

Height: 19 cm +/- 0.125 or 7.50 inches +/- 0.005

Width: 19 cm +/- 0.125 or 7.50 inches +/- 0.005

Wire Size and Pitch

The standard, in-stock diameter wire used for Z-Axis connector elements is 0.05 mm (0.002 inch). We are able to build connector elements with almost any size or shape wire (such as ribbon) and will respond to special requests for wire or ribbon as thin as 0.01078 mm (0.0007 inch).

The pitch of wires for most Z-Axis connector elements is 0.10 or 0.125mm (0.004 or 0.005 inch). We are able to offer closer or wider spacing depending on the requirements of the application. We are able to group wires on a repeatable basis and can place wires accurately from a reference edge or other physical feature.