Z-Axis elastomeric connectors are engineered for high-reliability applications, ensuring stable performance under extreme mechanical and environmental stress.

Our connectors have undergone rigorous shock, vibration, and temperature cycle testing, proving their robustness for mission-critical applications.

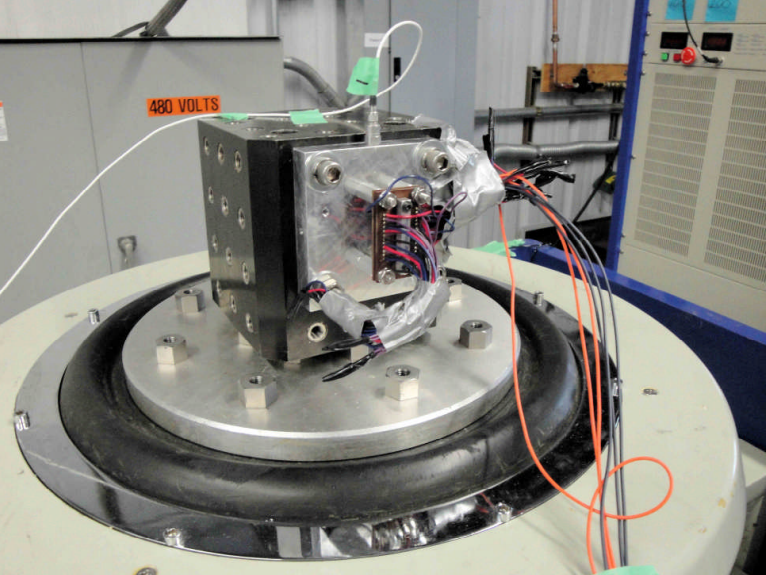

Vibration Testing

MIL-STD-1344A, Method 2005.1

Test Conditions:

- Vibration Level: 16.4 grms

- Duration: 3 minutes per axis (X, Y, Z)

- Monitoring: Continuous electrical continuity check with a 1 µs oscilloscope resolution

Results:

- No open circuits detected during testing

- Minimal change in contact resistance after vibration exposure

- Stable electrical performance in all three axes

Vibration Test Fixture

Key Takeaway: Z-Axis connectors maintain electrical continuity even under high-vibration conditions, ensuring long-term reliability in motion-heavy environments.

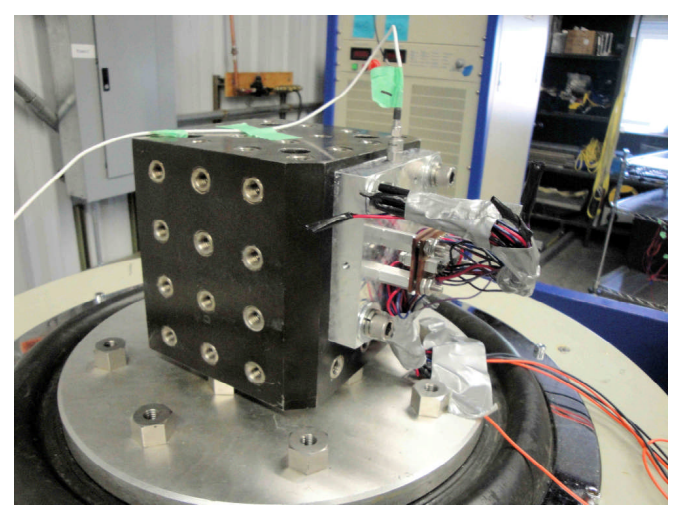

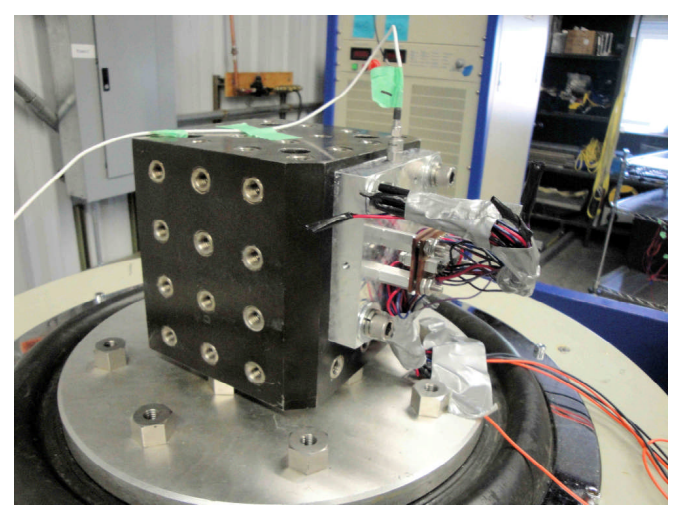

Temperature Cycling

MIL-STD-1344A, Method 1003.1

Test Conditions:

- Temperature Range: -55ºC to +100ºC

- Cycles: 100 thermal cycles

- Monitoring: Continuous electrical continuity check during cycling

Results:

- No open circuits detected throughout 100 cycles

- Stable insulation resistance and dielectric withstand voltage

- Minimal shift in contact resistance, confirming long-term durability

Vibration Test Fixture

Electrical Performance Validation

Additional testing confirmed compliance with MIL-STD-1344A standards for:

- Dielectric Withstand Voltage: Leakage current < 5 mA at 500VAC

- Insulation Resistance: >5000 MΩ at 250VDC

- Contact Resistance: < 25 mΩ for high-performance connectors

These results demonstrate that Z-Axis elastomeric connectors deliver consistent electrical performance even after exposure to severe mechanical and environmental stress.