For engineers and designers, the design and validation of PCB bring-up boards are often the foundational steps in creating new devices. These boards provide the first point of assessment, allowing for component verification and performance checks before final production.

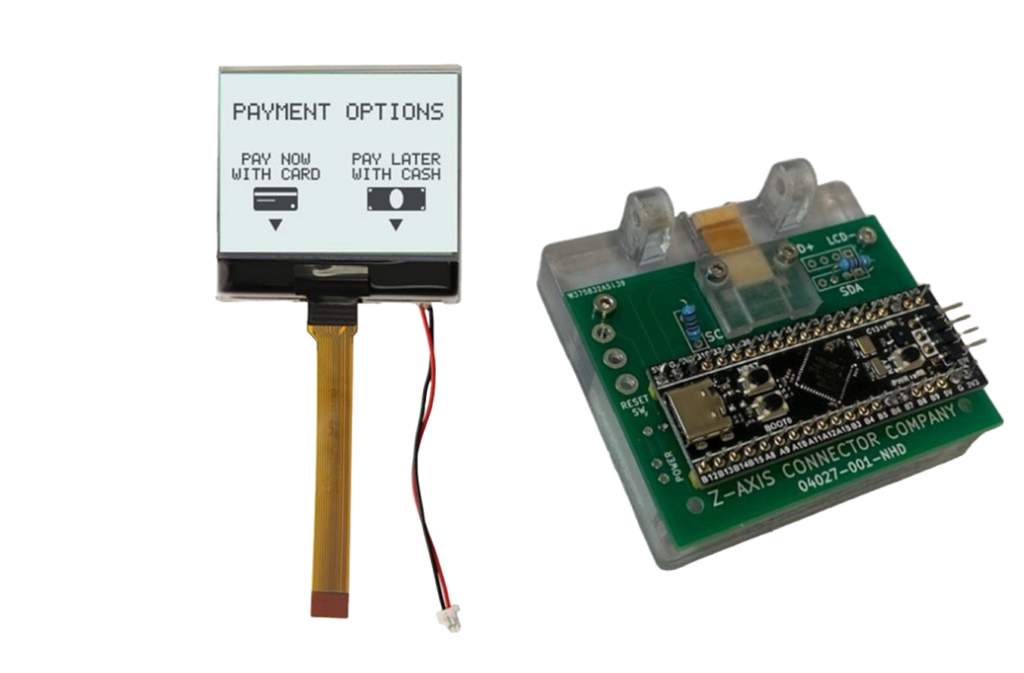

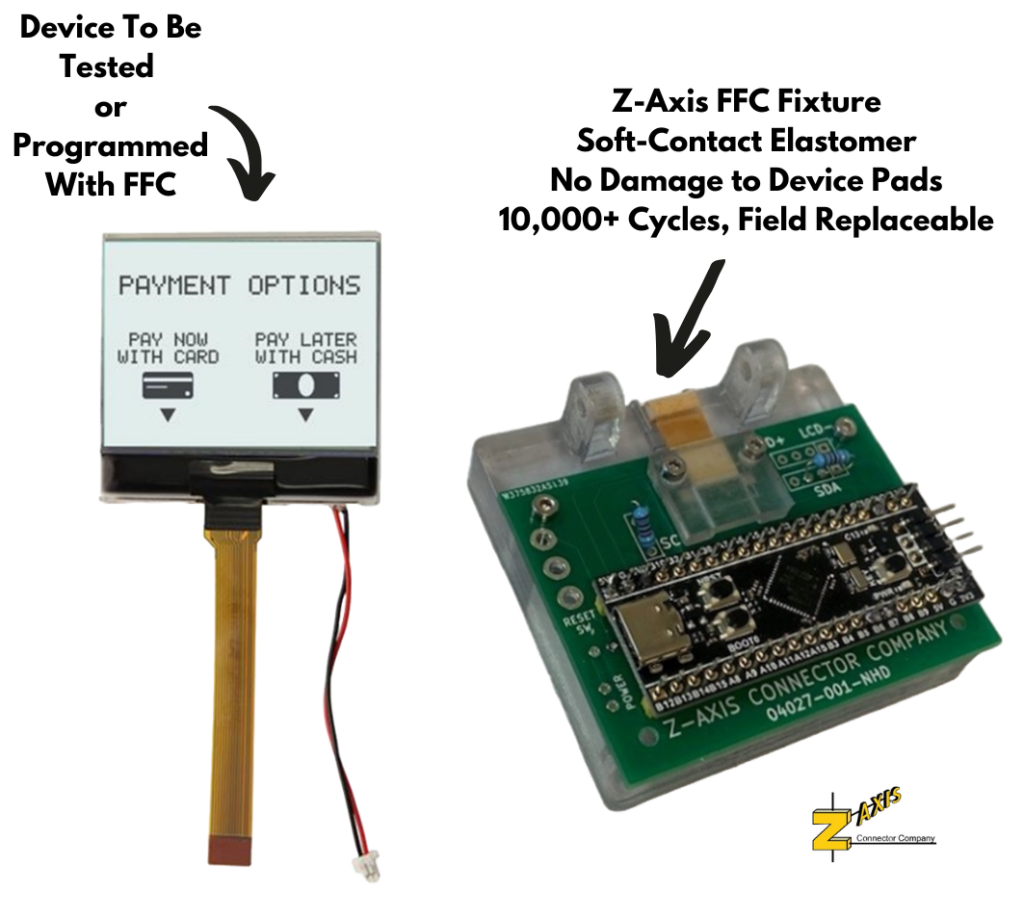

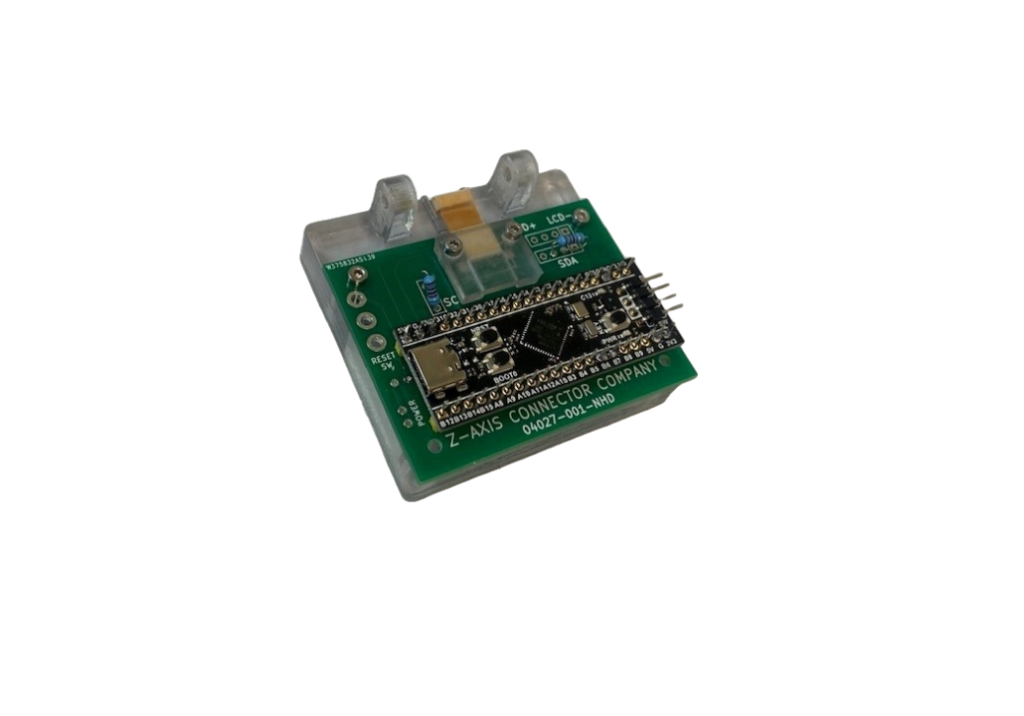

Yet, this process can be time-intensive and challenging, especially with traditional assembly and testing methods. Z-Axis Connector Company’s elastomeric connectors present a transformative solution, streamlining PCB bring-up board processes for efficient and reliable development.

The Challenge of PCB Bring-Up Boards

PCB bring-up boards are crucial for verifying component integrity and diagnosing potential issues early. However, conventional approaches to assembling and testing these boards involve extensive soldering, wiring, and precise alignment, often demanding significant attention to detail. Engineers can find themselves dedicating hours to this preliminary phase—time that could be redirected to innovation, optimization, and other critical design tasks. This is where elastomeric connectors redefine the process.

Elastomeric Connectors: Precision and Efficiency

Elastomeric connectors are a breakthrough for PCB bring-up boards, eliminating the need for intricate soldering and providing a straightforward, high-performance connection solution. By employing these connectors, engineers gain numerous advantages that enhance efficiency, accuracy, and flexibility. Here’s why elastomeric connectors are a valuable asset to modern electronics development:

- Significant Time Efficiency

Elastomeric connectors simplify the assembly process, allowing for fast, plug-and-play integration of components. Unlike traditional soldered connections, these connectors compress to create a reliable bond, drastically reducing the time required for assembly and ensuring swift connections. Engineers can rapidly configure and adjust board setups, expediting the entire bring-up phase. - Versatile Design Adaptability

Elastomeric connectors are highly customizable, fitting various PCB layouts and designs. Their adaptability makes them ideal for a wide spectrum of applications—from complex IoT and wearable devices to industrial equipment. Z-Axis Connector Company offers elastomeric connectors tailored to different layout configurations, so your team can seamlessly integrate them into unique and complex designs. - High Reliability and Consistency

Connection reliability is vital in electronics development. Elastomeric connectors from Z-Axis maintain a stable and consistent connection even under rigorous testing. Their uniform conductivity ensures that signal integrity is preserved, minimizing the risk of connection failures during critical testing phases and preventing disruptions that can delay the project timeline. - Simplified Troubleshooting and Debugging

Efficient debugging is crucial in the bring-up stage. Elastomeric connectors allow engineers to access and isolate individual components easily, facilitating rapid diagnostics. Unlike soldered setups that can be cumbersome to dismantle, elastomeric connectors support efficient reconfiguration and troubleshooting, saving time during the debugging process. - Cost-Effective Long-Term Solution

By reducing the labor and time associated with PCB bring-up board assembly, elastomeric connectors contribute to long-term cost savings. With Z-Axis connectors, engineering teams can accelerate project timelines without compromising quality, allowing resources to be allocated to other core tasks that enhance project outcomes and accelerate time-to-market.

Empowering Engineers with Efficient Solutions

PCB bring-up board challenges should not hinder the development process. Elastomeric connectors empower your team to transition seamlessly from initial testing to production-ready designs. At Z-Axis Connector Company, we specialize in designing high-quality elastomeric connectors to meet the demands of today’s electronics projects.

Ready to optimize your next project? Contact us today!