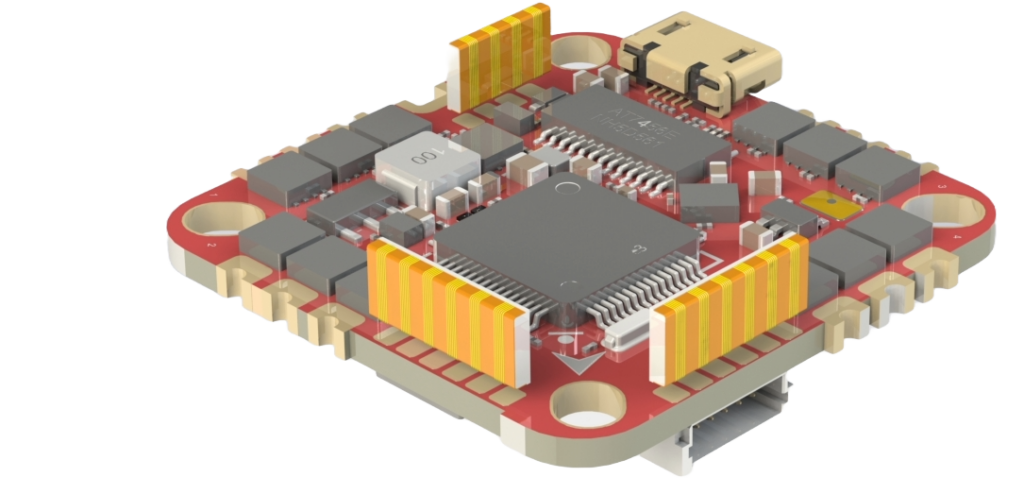

Designing electronic systems requires components that are as flexible as the challenges engineers face. One of the most common bottlenecks in design is managing the need for multiple board-to-board connection styles, such as parallel and 90-degree alignments. Traditional approaches often involve stocking multiple connector types, leading to increased costs, inventory complexity, and design constraints.

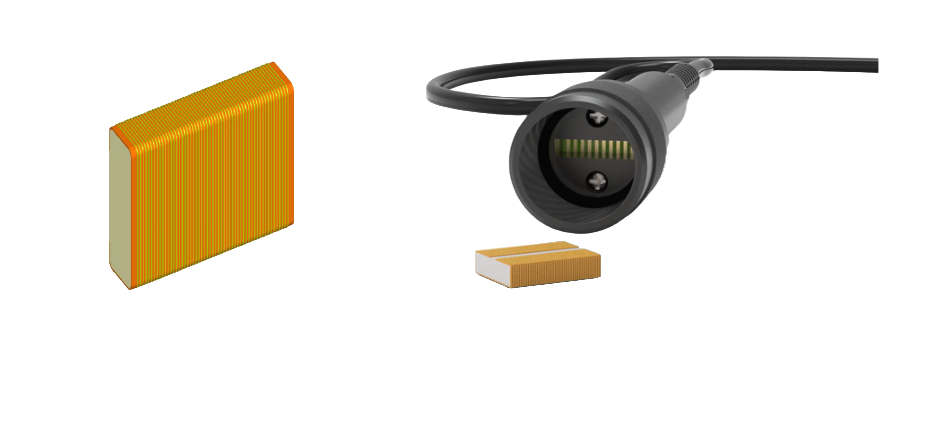

With Z-Axis Connector Company, a single connector is capable of delivering reliable connections in both parallel and 90-degree configurations.

Why This Matters

Typical board-to-board connectors are optimized for only one configuration, forcing designers to either:

- Redesign the PCB layout to accommodate connector limitations, or

- Source additional connector styles, increasing BOM complexity and cost.

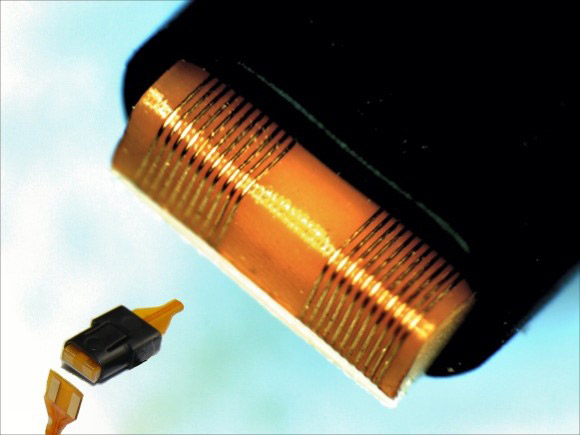

Z-Axis elastomeric connectors solve both problems by offering dual-configuration compatibility in a single, compact design.

Technical Specifications

Our connectors are engineered to meet the needs of diverse applications while maintaining performance and durability:

- Contact Pitch: Available in 0.5mm, 0.8mm, and 1.0mm to suit a range of applications, from microcontrollers to power delivery.

- Contact Resistance: <20 milliohms per contact, typical

- Current Rating: 500 milliamperes per 0.015” pad

- Capacitance Between Conductors: < .3pf between pads

- Inductance: < 0.05 nanohenries from 5 to 500 kHz

- Core Material: Silicone rubber

- Core Durometer: 50 Shore A, standard

- Film: 0.001” Polyimide, standard

- Humidity Range: 0-100%

- Temperature Range: -65° F to +250° F

- Dielectric Withstanding Voltage: 500V rms, minimum

Traditional connectors are purpose-built for either parallel board-to-board alignment or 90-degree configurations. While these products serve their roles well, they often limit flexibility. For engineers, this can mean managing complex inventories, higher costs, and lost time sourcing multiple components to accommodate diverse designs.

Z-Axis connectors eliminate these challenges by delivering unparalleled versatility. With a single connector, you can achieve reliable, high-quality connections for both parallel and 90-degree setups, reducing your overall component count while enhancing design flexibility.

Real-World Applications

Here are specific examples of how Z-Axis connectors excel across industries:

- Medical Devices

Portable diagnostic equipment often requires modular PCBs that can be replaced or upgraded without changing the entire system. Z-Axis connectors provide flexibility for both stacked (parallel) configurations and right-angled connections for compact housings. - Wearable Technology

Smartwatches and fitness trackers have extremely limited internal space. A 90-degree connection might be needed to fit components within the curved housing, while parallel alignment can optimize the initial testing stages. - CNC Machines and Robotics

In industrial automation, controllers, sensors, and actuators often require robust and adaptable board-to-board connections. The ability to switch configurations during upgrades or maintenance is a significant advantage for these dynamic systems. - Automotive Electronics

Automotive ECUs (Electronic Control Units) often have tight spatial constraints. Using a single connector for both configurations simplifies assembly, particularly in modular designs where reconfigurations are common. - Consumer Appliances

Consider a smart kitchen appliance where PCBs for user interfaces and sensors must connect at varying angles depending on the model. Z-Axis connectors provide the flexibility needed to adapt across product lines.

The Cost and Efficiency Edge

Using Z-Axis elastomeric connectors reduces:

- Procurement Overhead:

- A single part number for multiple applications.

- Time to Market:

- Simplified prototyping and fewer reworks during design changes.

- Risk of Obsolescence:

- Long-term flexibility ensures your connector choice remains relevant as designs evolve.

With fewer components to manage, your team can focus on innovation, knowing that connectivity challenges are already solved.

Why Choose Z-Axis?

Reliability: Tested under rigorous conditions, ensuring consistent performance across configurations.

Simplicity: Easy to integrate, with straightforward PCB footprint designs provided for both configurations.

Support: Our engineering team is available to assist with customizations or design consultations to ensure a perfect fit for your project.

Get Started Today

Contact us to request detailed specifications, engineering samples, or design guidelines. Our team is ready to help you integrate Z-Axis connectors into your next project and experience the benefits of unmatched versatility and cost efficiency.